As soon as the resources are processed right into a bulk product, they are then packaged. The focus of the area is on preserving the product plus the surfaces it encounters. In the case of stable dosage kinds, present designs for packaging traces together with capping inside a filling suite that satisfies the exact same ISO eight Class 100,000 environmental requirements as the procedure suite exactly where the products was made. The classification prerequisite may vary depending on the task.

Regardless of these strategies, the potential from the procedure to generate sterile merchandise needs to be validated to function in accordance with pre-set up conditions.

The design will help assure shoppers have a upcoming-proofed system that only requires a six-pound charge of refrigerant. This eliminates the need for a bigger refrigerant charge and probable leak threat.

Substitute media to Those people stated can be utilized furnished that they're validated for the objective meant.

The sort of medium, liquid or good, that is definitely useful for sampling or quantitation of microorganisms in managed environments will depend on the procedure and products made use of.

Documentation and Validation: Every single step with the cleanroom operation, from environmental checking to cleaning methods, should be documented to guarantee compliance with regulatory standards and provide traceability throughout inspections or audits.

Pharmaceutical goods, particularly sterile medications and biologics, call for an atmosphere free of contaminants to forestall prospective damage to clients and make sure the efficacy in the products.

This change is driven from the rising complexity of drug formulations and the need for larger levels of contamination Management in the production of delicate biopharmaceuticals and mobile therapies.

One of several significant limitations of mechanical air samplers could be the limitation in sample size of air staying sampled. Where the microbial stage within the air of a managed setting is predicted to incorporate not a lot more than three cfu check here for each cubic meter, numerous cubic meters of air need to be tested if benefits are to become assigned an affordable volume of precision and precision. Generally this isn't sensible. To show that microbial counts present from the environment usually are not raising with time, it would be needed to prolong some time here of sampling to ascertain if the time of sampling is a restricting variable or not.

All courses of clean rooms, airborn particles and components to work out the number of sampling places.

AdvanceTEC, in which experts with many years of segment practical experience apply the newest electronic resources and systems to provide excellent outcomes for you.

In regards to an average non-sterile pharmaceutical production facility, you'll find 6 basic places. These 6 parts are:

Just about every classification serves a specific reason, making certain that the extent of contamination Handle matches the producing stage’s requires.

The sampling plans should be dynamic with checking frequencies and sample approach destinations adjusted determined by trending overall performance. It is suitable to enhance or decrease sampling depending on this efficiency.

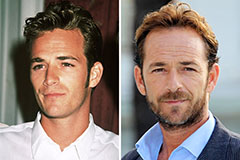

Luke Perry Then & Now!

Luke Perry Then & Now! Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!